- Topic1/3

946 Popularity

23k Popularity

5k Popularity

4k Popularity

170k Popularity

- Pin

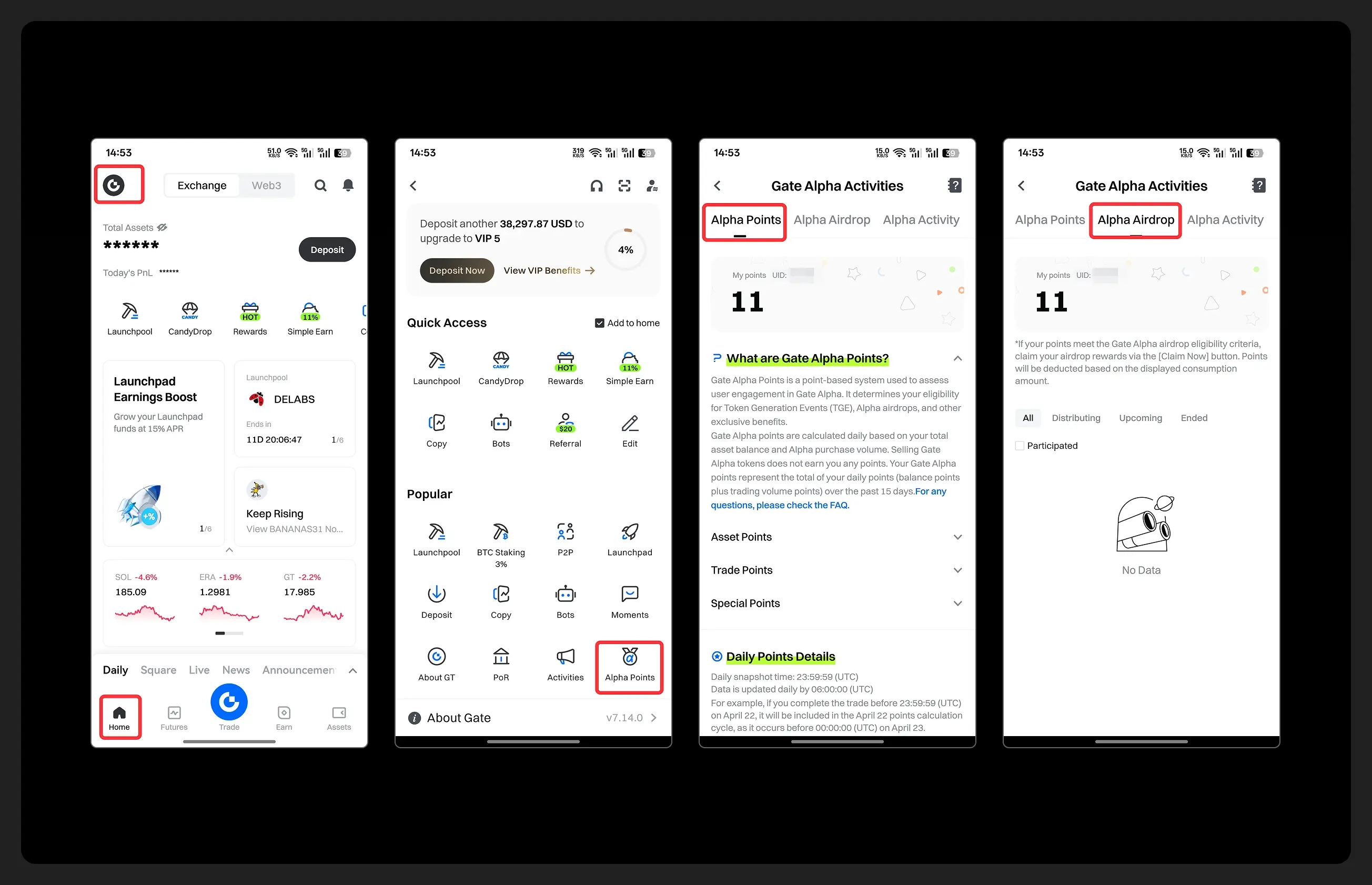

- Hey fam—did you join yesterday’s [Show Your Alpha Points] event? Still not sure how to post your screenshot? No worries, here’s a super easy guide to help you win your share of the $200 mystery box prize!

📸 posting guide:

1️⃣ Open app and tap your [Avatar] on the homepage

2️⃣ Go to [Alpha Points] in the sidebar

3️⃣ You’ll see your latest points and airdrop status on this page!

👇 Step-by-step images attached—save it for later so you can post anytime!

🎁 Post your screenshot now with #ShowMyAlphaPoints# for a chance to win a share of $200 in prizes!

⚡ Airdrop reminder: Gate Alpha ES airdrop is

- Gate Futures Trading Incentive Program is Live! Zero Barries to Share 50,000 ERA

Start trading and earn rewards — the more you trade, the more you earn!

New users enjoy a 20% bonus!

Join now:https://www.gate.com/campaigns/1692?pid=X&ch=NGhnNGTf

Event details: https://www.gate.com/announcements/article/46429

- Hey Square fam! How many Alpha points have you racked up lately?

Did you get your airdrop? We’ve also got extra perks for you on Gate Square!

🎁 Show off your Alpha points gains, and you’ll get a shot at a $200U Mystery Box reward!

🥇 1 user with the highest points screenshot → $100U Mystery Box

✨ Top 5 sharers with quality posts → $20U Mystery Box each

📍【How to Join】

1️⃣ Make a post with the hashtag #ShowMyAlphaPoints#

2️⃣ Share a screenshot of your Alpha points, plus a one-liner: “I earned ____ with Gate Alpha. So worth it!”

👉 Bonus: Share your tips for earning points, redemption experienc

- 🎉 The #CandyDrop Futures Challenge is live — join now to share a 6 BTC prize pool!

📢 Post your futures trading experience on Gate Square with the event hashtag — $25 × 20 rewards are waiting!

🎁 $500 in futures trial vouchers up for grabs — 20 standout posts will win!

📅 Event Period: August 1, 2025, 15:00 – August 15, 2025, 19:00 (UTC+8)

👉 Event Link: https://www.gate.com/candy-drop/detail/BTC-98

Dare to trade. Dare to win.

South Korea's biggest IPO this year will be Doosan Robot, which will make fried chicken, coffee and beer

Recently, Doosan Robot, South Korea's largest collaborative robot manufacturer, caused a sensation with a $312 million IPO. Doosan Robotics has recently developed a robot that can assist humans with household chores, such as making coffee, making fried chicken, serving beer, and carrying luggage.

Instead of reducing the cost of food, it is better to increase the efficiency of production, which is one of the reasons why robot manufacturers are the most sought after stock category in South Korea this year**. So, what is the origin of this company?

01.The robot factory behind the chaebol

Doosan Robotics is a collaborative robot company backed by Doosan Group, Korea's oldest and most famous conglomerate.

After three years of continuous research and development, Doosan Robot has successfully released its first robot that can work with humans to perform tasks in an efficient manner, thereby increasing productivity.

Doosan robots offer world-class performance with a working radius of 900-1700mm, a load capacity of 9-15kg, and sensitive collision detection sensors to ensure the safety of nearby workers. Strong sales growth of 49% on average over the last 3 years since commercial production began in 2018.

With such ambitious goals, what are the characteristics of its products?

02. Diverse cobots

Since its establishment in 2015, Doosan Robot has been committed to providing diversified collaborative robot products to the global market, and has been continuously innovating, and has been used in various industries such as manufacturing, logistics, catering, and healthcare.

Three Traditional Cobots

In 2017, Doosan's Collaborative Robotic Arm M Series debuted. The M series consists of a robotic arm, controller, PC programming software and an emergency stop button. Its unique feature is the use of a high-performance six-axis torque transducer for precise operation control. Therefore, the M series is mainly used in delicate work and medical scenarios in the industrial field.

This collaborative robot can be applied to multiple scenarios, for example, it can work with workers to assemble an industrial hydrogen fuel drone; Realize various tasks such as conveyor line tracking, welding, gear assembly, and more. In addition, the A-series robots can also demonstrate the skills of an amazing barista and painter.

In addition to the application of traditional industrial fields, Doosan's H-series robots are also attracting attention in the field of art. Doosan's photography robot "NINA" won the CES 2022 Best Innovation Award. Using software with an intuitive UI and shared camera motion presets, this robot makes it easy for content creators to capture high-quality work.

Machine revolution in food preparation

In April, Doosan unveiled its blockbuster E-Series collaborative robots, designed specifically for the food industry. With a base load of 5kg and a working radius of 900 mm, the E-series robots can be widely used to produce a wide range of food and beverages, such as coffee, ice cream and fried foods.

Compared to existing collaborative robots, the E-series robots are smaller and have a wired design that simplifies the installation process. Designed with an anti-contamination coating and sealing gap between connecting shafts, the robot has been certified for food hygiene and safety by the National Sanitation Foundation (NSF).

E series robots are committed to efficient and safe food preparation, and with their precise operation ability and versatility, they can meet most Korean food preparation needs.

In addition, Doosan Robot is actively working with partners in the catering industry to further expand the scope of its food robot applications. In the future, it will cover more fields such as confectionery making, fast food, and barbecue.

It is worth noting that with the explosion of AI this year, large manufacturers have entered the production of various creative applications, and Doosan has not fallen behind. The company plans to realize AI-based automation and intelligence upgrades by integrating GPT in robots**. For example, the E-Series robot combined with GPT can prepare dishes based on simple voice commands from the user and automatically find the best order of tasks to meet the needs of customized tastes.

In addition, the integration of GPT enables the robot to access and learn from existing code databases, saving programming time and effort. Doosan Robotics plans to test the technology in the food and beverage industry and consider applying the technology to manufacturing after success.

03.Soaring market and difficulties

Although robot financing has overshadowed artificial intelligence, there are only a handful of profitable companies across the market. The blue-collar labor shortage shows a huge gap, but the technology and capital needed to achieve mechanization are even more difficult.

Burn money just to stand firm in the market

According to the "2023 World Robot Report" recently released by the International Federation of Robotics (IFR), 553,052 new industrial robots were installed in factories worldwide, with a year-on-year growth rate of 5%, and are expected to grow by 7% in 2023, more than 590,000 units, of which 73% are installed in Asia.

According to a report by Markets and Markets, the global collaborative robot market is expected to reach $1.2 billion this year and $6.8 billion in 2029. But the robot market seems to be hot, and the scale of financing is huge, but in fact, it burns money quickly and cannot make ends meet. Even as the first company in South Korea to sell 1,000 collaborative robots a year, Doosan Robotics still posted huge losses, with revenue of 44.9 billion won (approximately 242 million yuan) and operating loss of 13.2 billion won (more than 70 million yuan) in 2022.

However, both investors and Doosan are full of confidence in collaborative robots, which are easier to deploy and quickly scaled up unlike industrial robots, which are also widely used in various scenarios, including industry. Doosan Robot President Yoo Jung-hoon also publicly issued a petition, saying that the company will be profitable in 2024.

**Do you need machines for catering? **

Will focusing on catering enable Doosan Robot to achieve its goal of securing the collaborative robot industry? In fact, whether in South Korea or China, in the catering industry, collaborative robots may already be around you. However, compared with Doosan robots, which are mainly oriented to fast food beverage services, domestic catering robots are more responsible for the role of delivering dishes to the table and stir-frying.

Returning to the layout of Doosan robot, first of all, it is not a pre-made dish, but assists in food production in fast food restaurants, and secondly, its current application scenarios - fried chicken, coffee, beer, it is difficult to say that people will still be sober about health and wellness when choosing these three foods**. Just like a certain duck neck that relies on self-explosion and is full of technology without emotion, the flocking foodies are still flowing.

04.The ritual sense of technology

In the future, after the large-scale use of robots in the catering industry, will customers be willing to pay for technological food? In Asia, China has eight major Chinese cuisines, Japan has the craftsmanship of cuisine, and the food desert of South Korea has become a fertile ground for the rapid development of robot processing food**.

Whenever the brain appears "I need this food", the robot can start working instantly, bringing you the satisfaction you need, which is not the ritual sense that technology gives to humans?